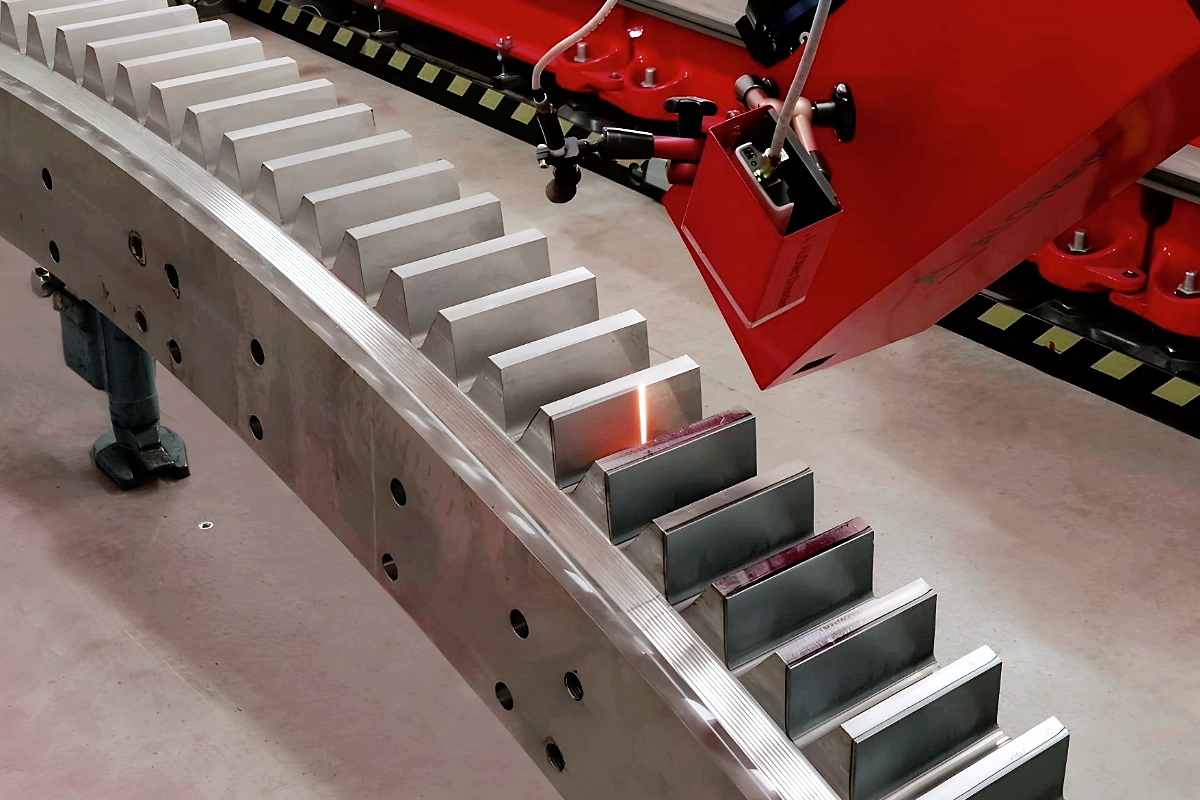

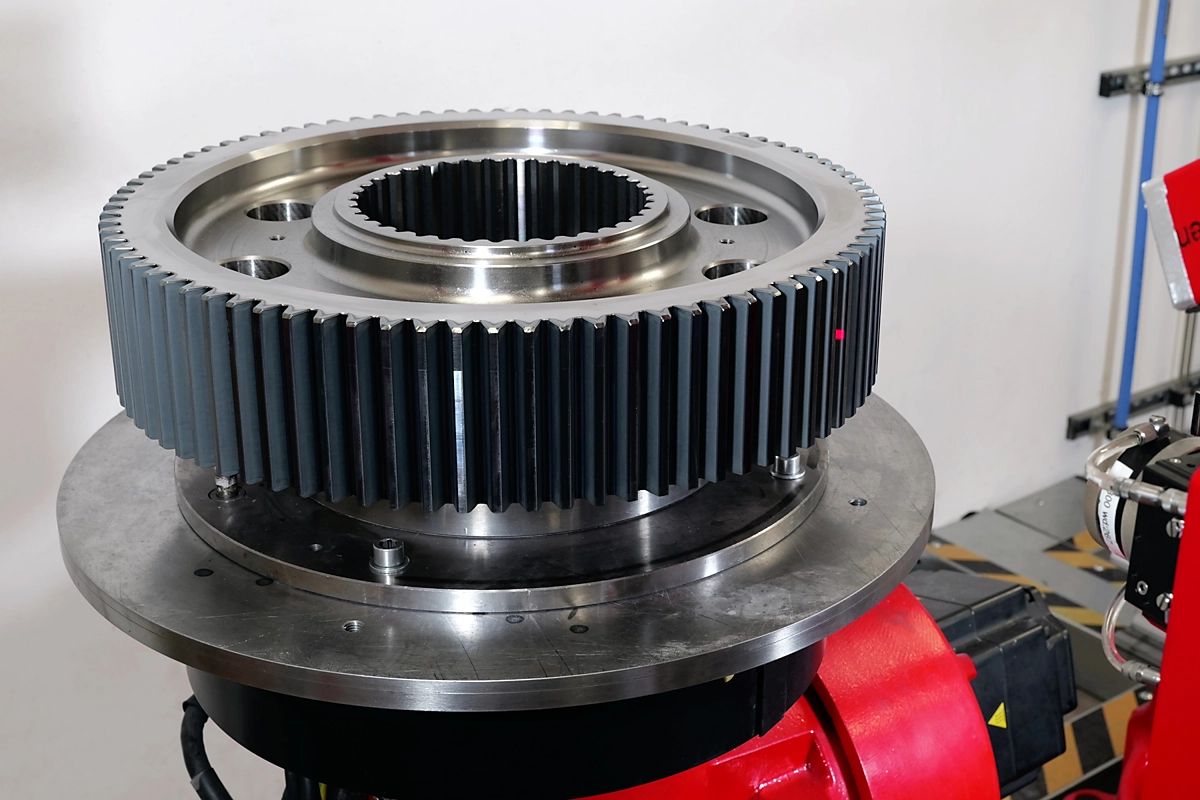

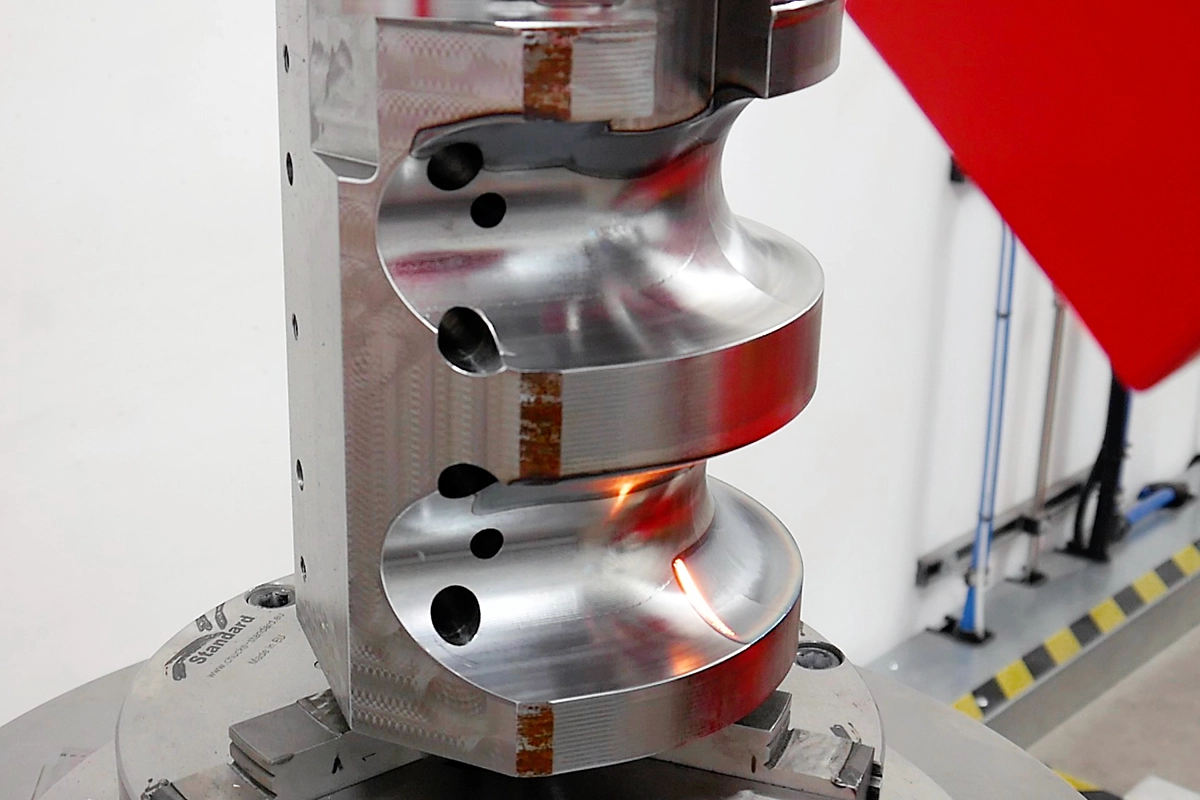

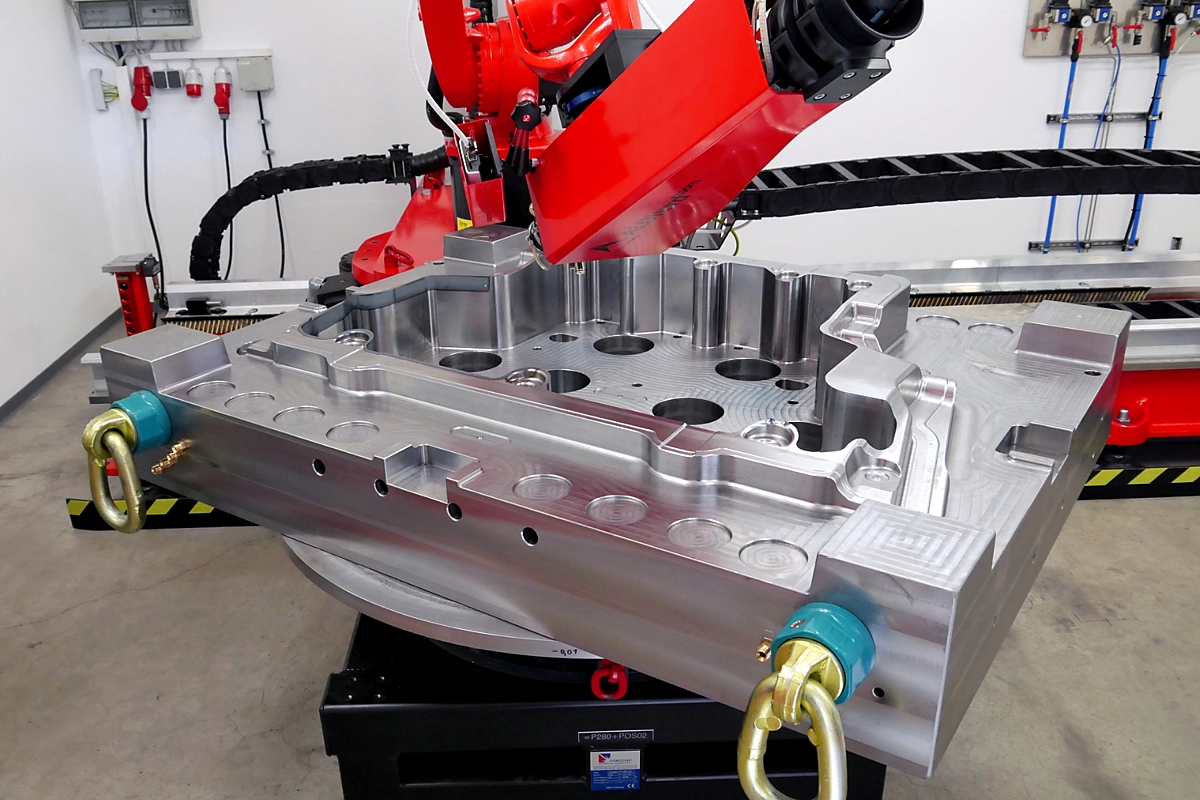

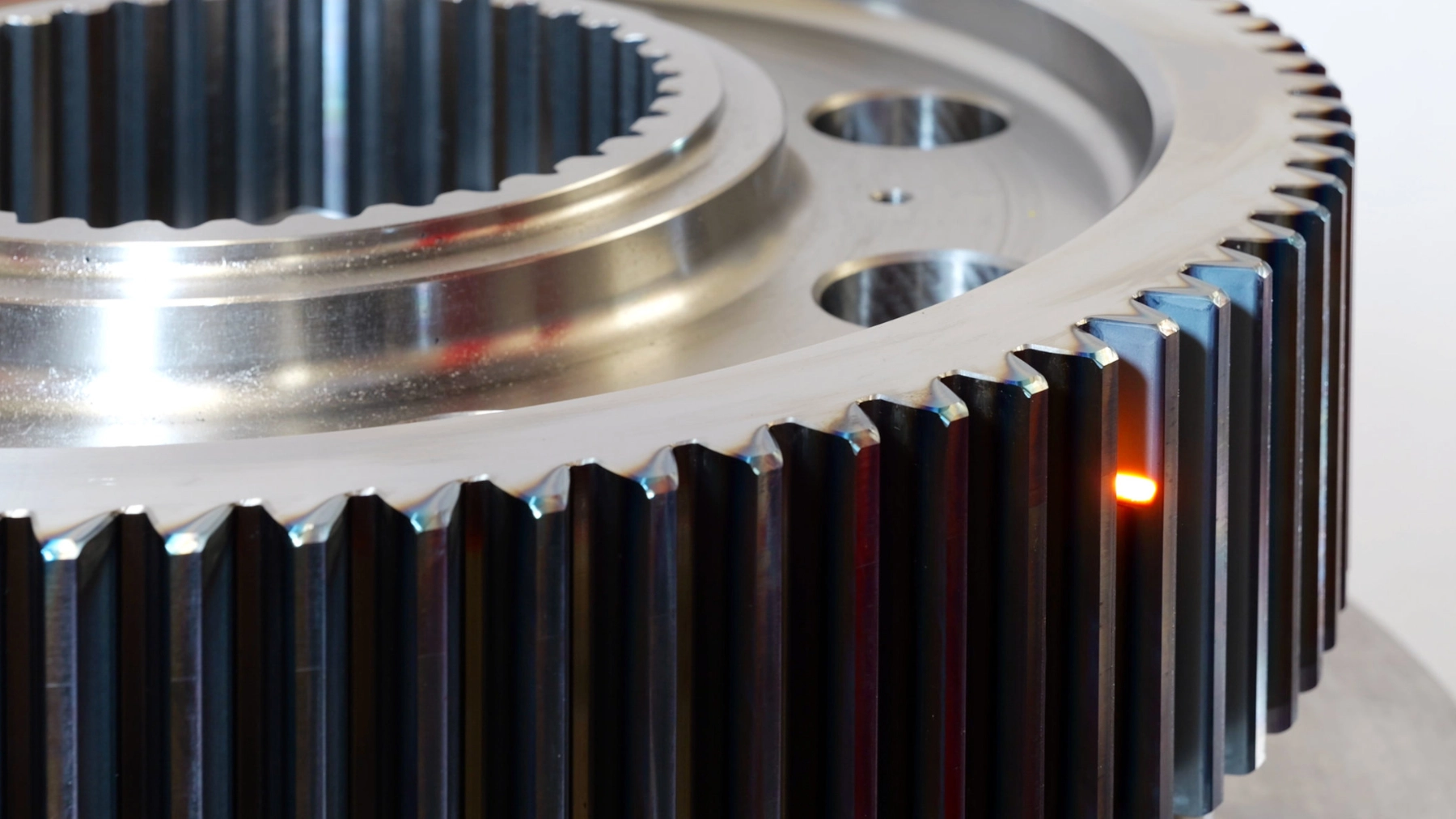

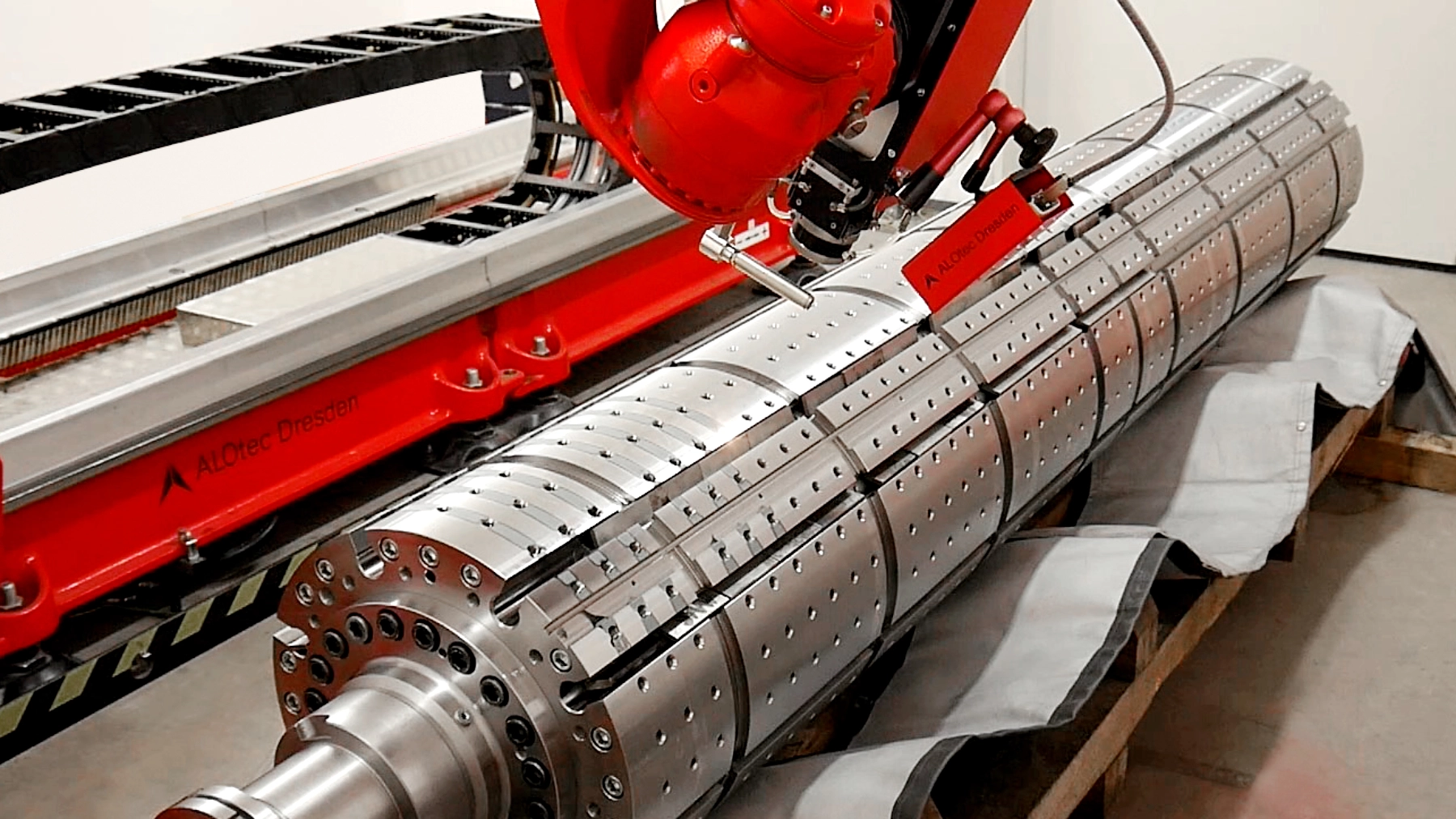

Surface hardening of the tooth flanks on a large gear rim (mining).

- Laser hardening with scan optics

- entire tooth flank hardened in one track

- No tempering effect

- Weight: 950 kg, length: 4 m (per sprocket segment)

Wear protection – precise and efficient

Laser hardening

Protect your components – before wear stops your production.

Unplanned downtime, expensive repairs, production delays: Component failure costs time and money. With our precise laser surface hardening, you can increase the stability of your components in a targeted manner – economically, efficiently and with virtually no distortion.

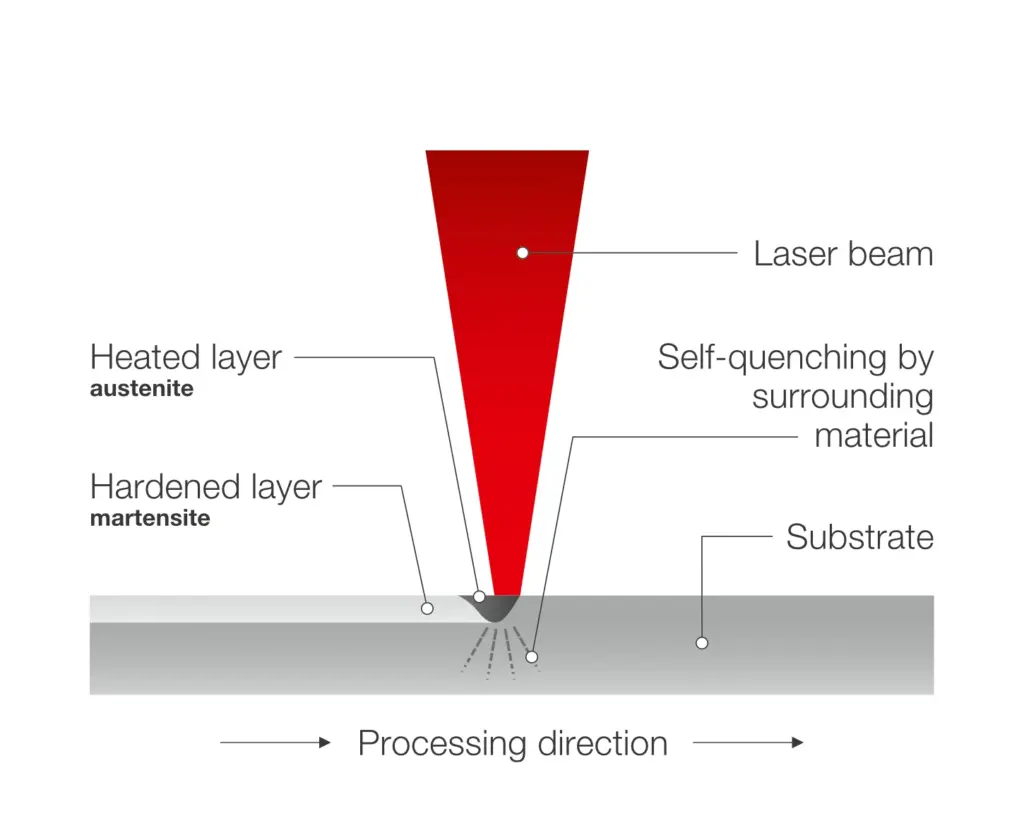

In laser hardening – an effective and precise form of surface hardening – the surface of your workpiece is precisely heated and then rapidly quenched by the component volume. The result: an extremely hard, wear-resistant surface layer with a tough core material – ideal for the highest loads and reduced post-processing costs.

Secure your components for the long term – get a non-binding consultation now!

High surface hardness

Produces high surface hardness with a tough material core

Minimal distortion

Minimal distortion of the component due to low heat input

No quenching media

No quenching media are required

No hard milling required

No hard milling is required

Homogeneous hardness

Homogeneous surface hardness in a clearly defined range

Sustainable

100 x more energy-efficient than through-hardening and resource-saving

High precision

Hardening of hard-to-reach contours on complex, intricate components

High productivity

Faster throughput times, even single pieces or small batches possible

Laser hardening – refinement for many applications

Laser hardening is used in the finishing of highly stressed, complex components and is used in industry, automotive, railroads, mechanical engineering, toolmaking, mold making, the oil and gas industry, mining, shipbuilding and agricultural engineering.

Automotive and mold making

Machine and gear construction

Agriculture and engineering

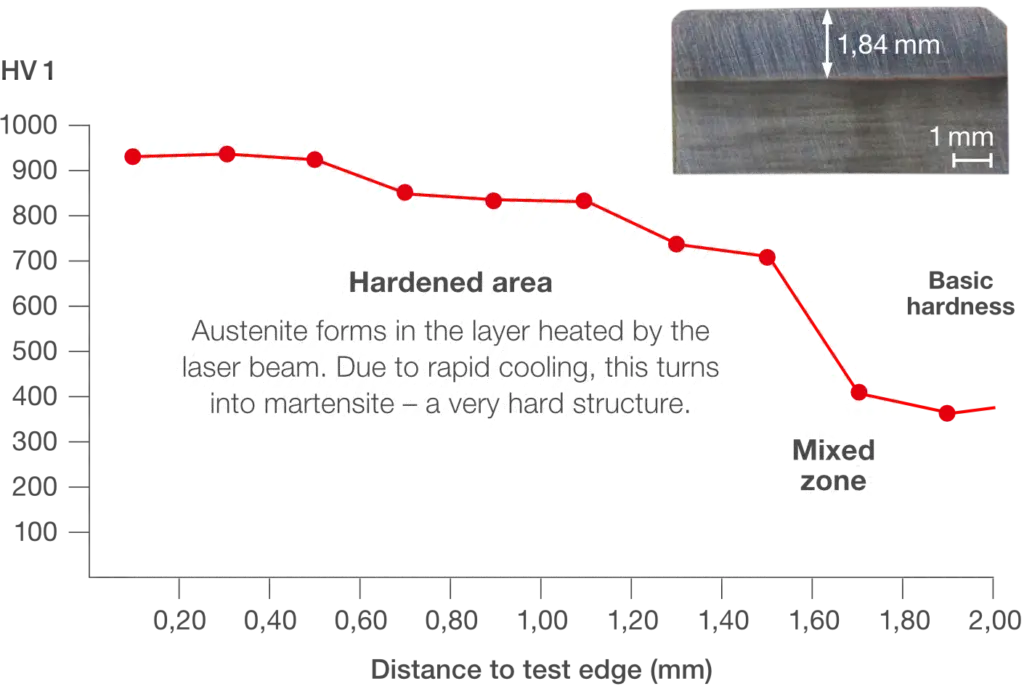

Laser hardening is a surface layer hardening process that achieves maximum hardness values on the surface layer of carbon-containing components made of steel or cast iron with minimum energy input. The aim is to improve wear behavior.

The laser beam briefly and precisely heats the top layer of the material to the austenitization temperature of the material used. This heating causes a restructuring of the carbon atoms in the metal lattice and creates an austenitization front in the material. No additional quenching medium is required due to the self-quenching, which takes place via the volume of the component. The rapid cooling leads to the formation of martensite, which results in a significant increase in hardness.

Thanks to its precision and efficiency, laser hardening is a particularly environmentally friendly and resource-saving technology. It is particularly suitable for small series and individual pieces, as it is extremely economical in these areas.

Surface hardening of the tooth flanks on a large gear rim (mining).

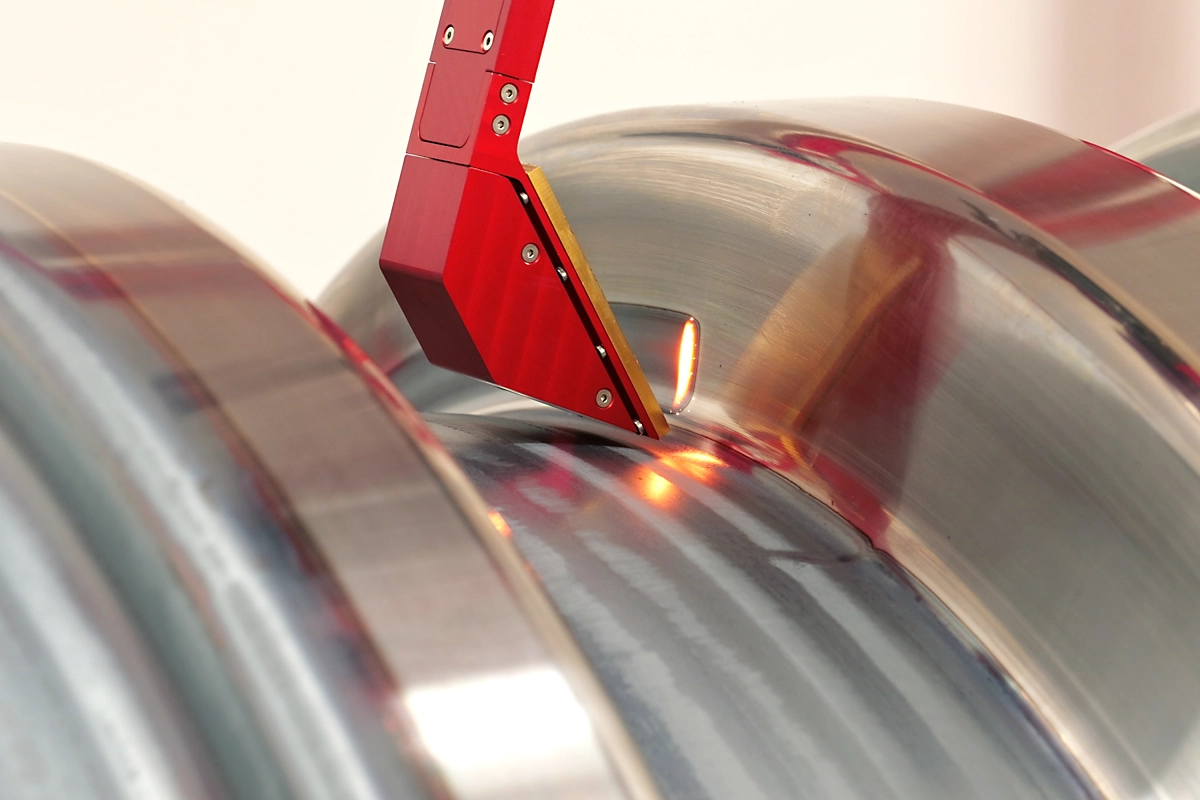

Targeted laser hardening of the tooth geometry of a drive gear to 56 HRC.

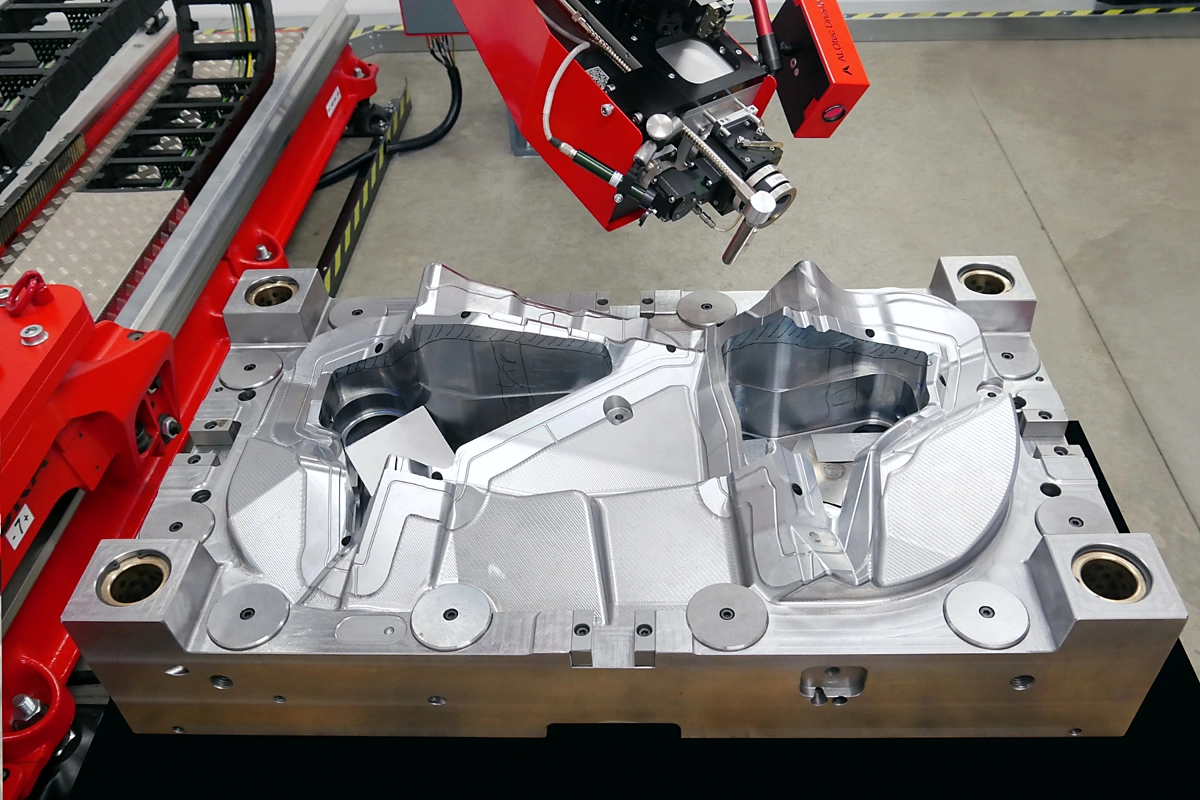

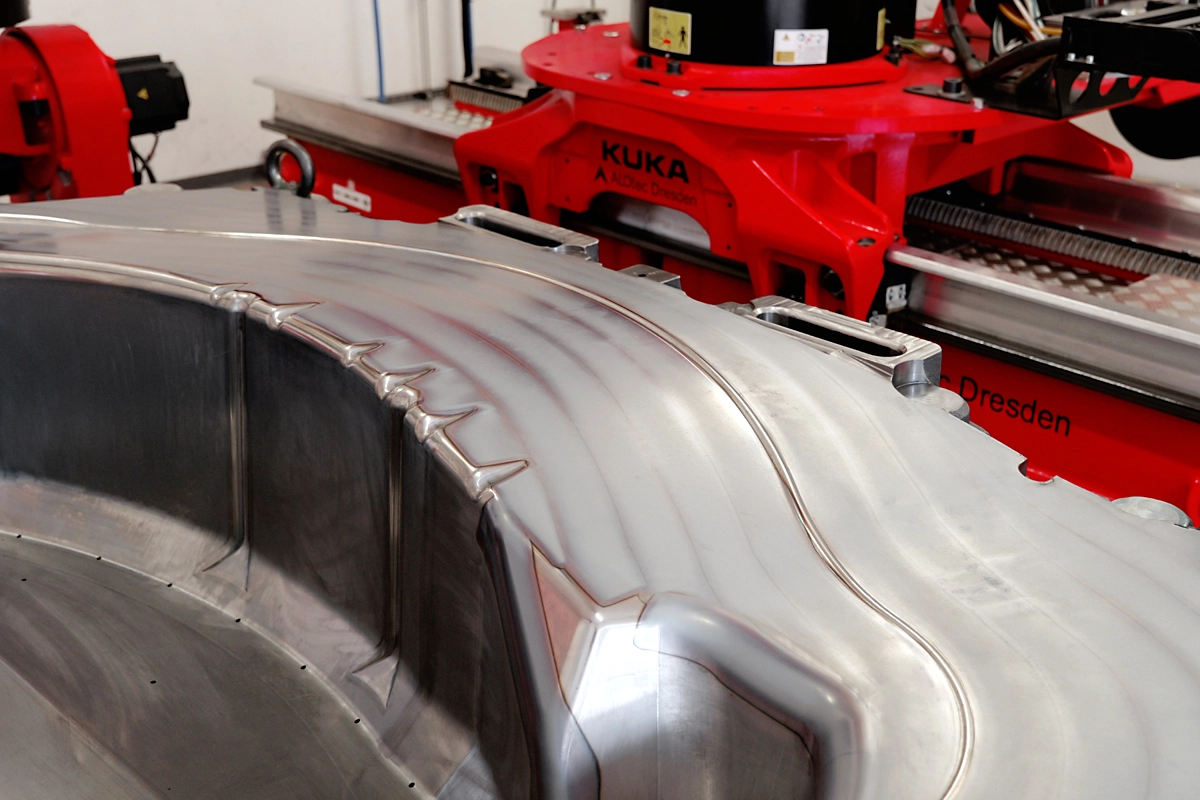

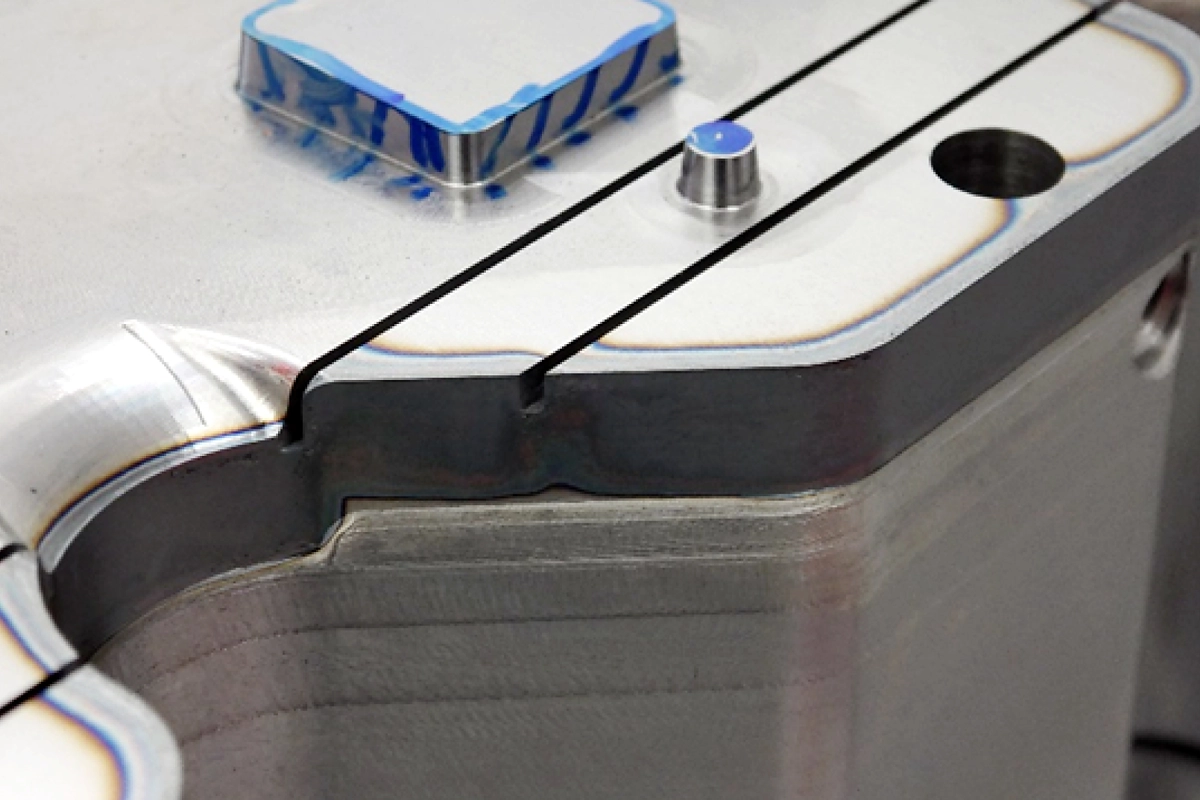

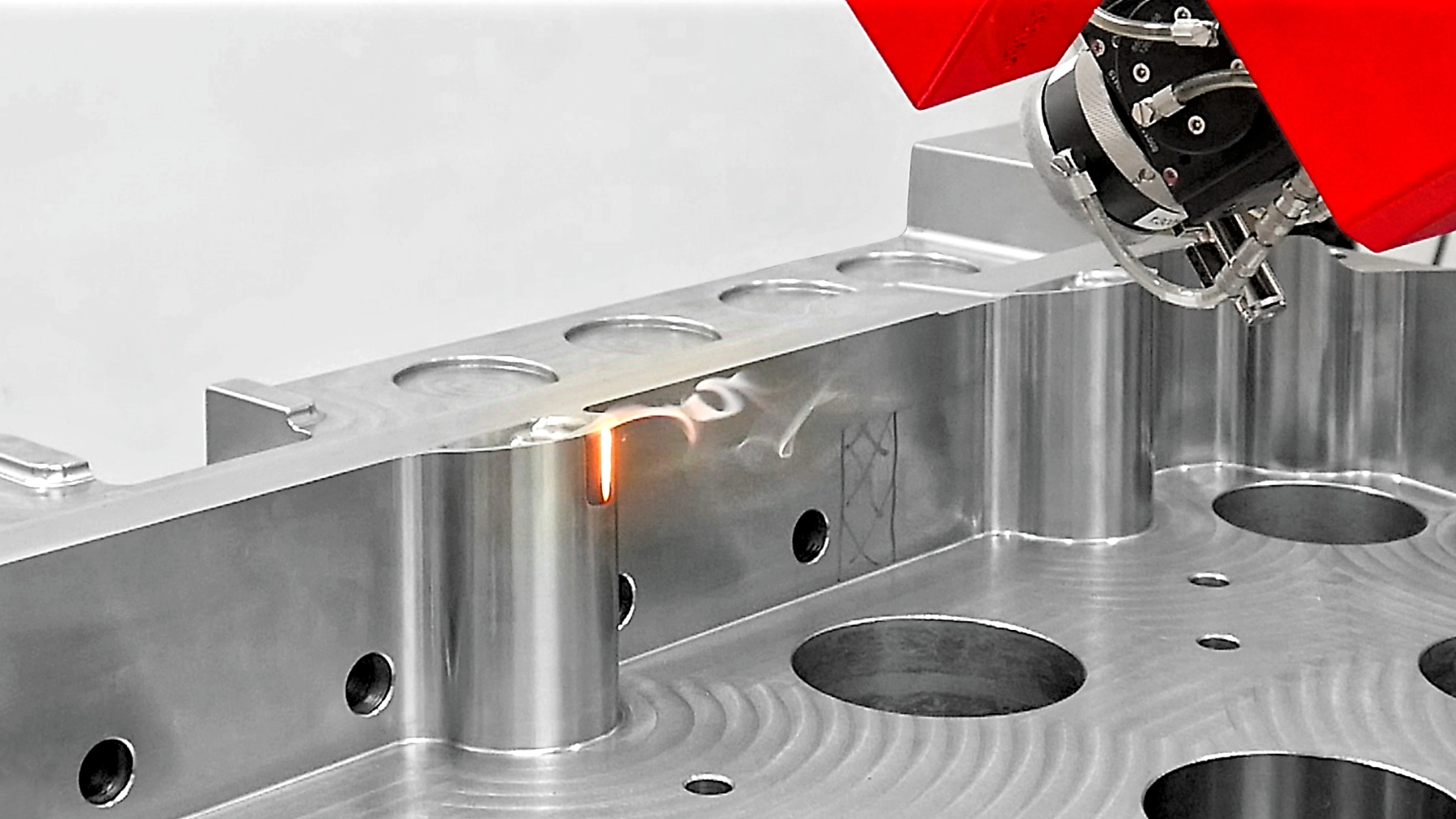

Laser hardening of a forming tools with dynamic laser beam guidance independent of the component geometry.

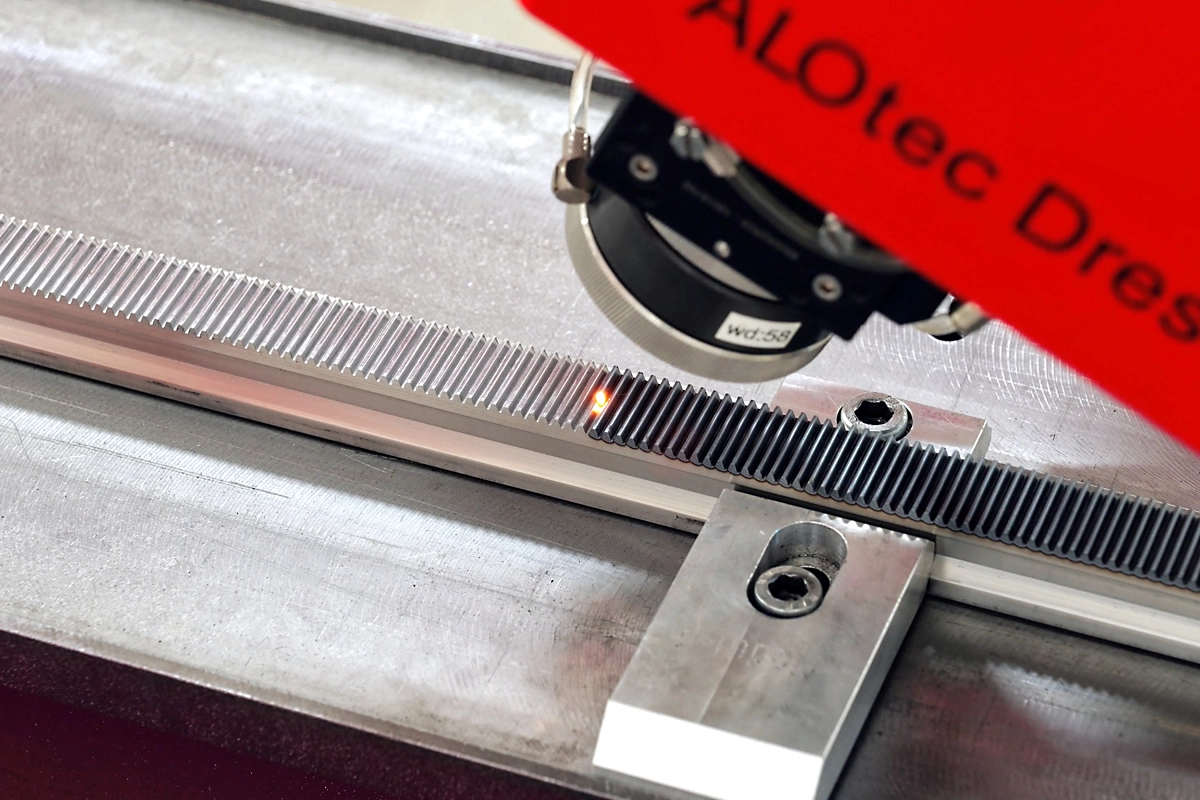

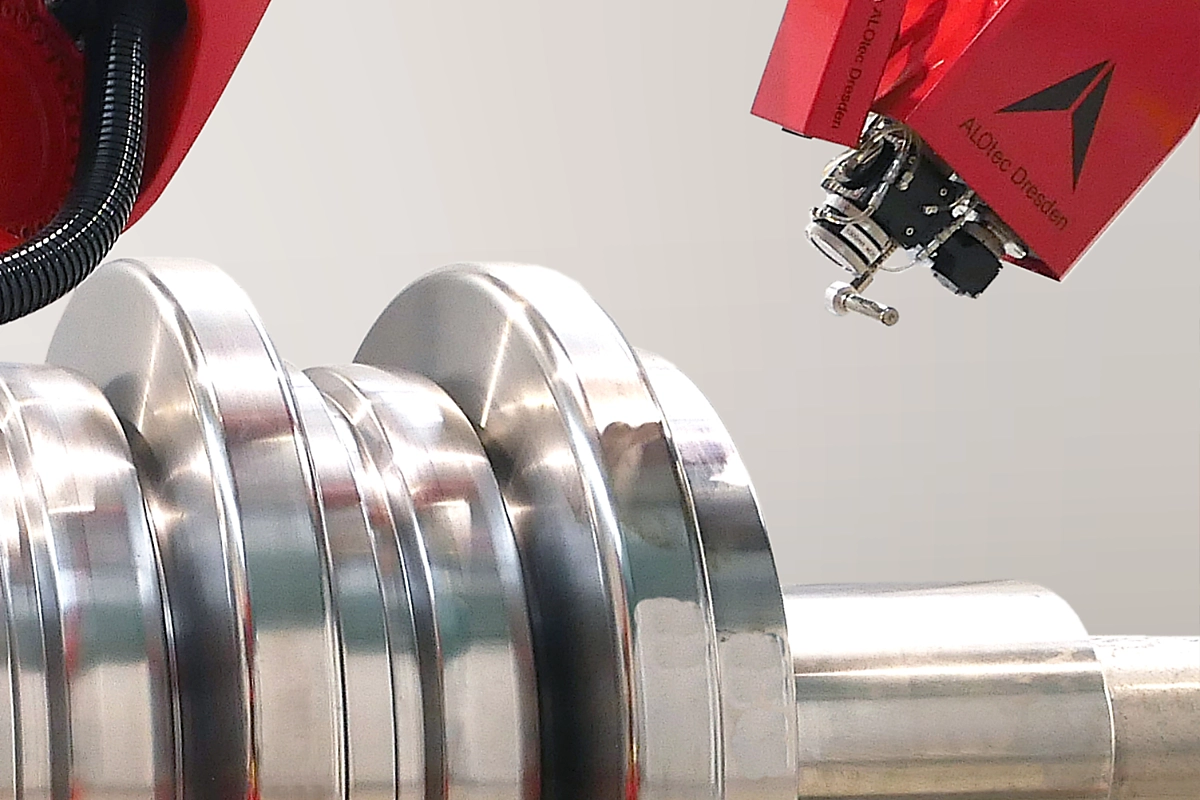

Laser hardening with variable laser track width enables precise adaptation to different tooth geometries.

The post-processing costs could be reduced by 30 % compared to induction hardening.

Laser hardening on all surfaces of a forming tool that are subject to heavy wear. The variable laser track width makes it possible to react to a wide variety of component geometries of the tool.

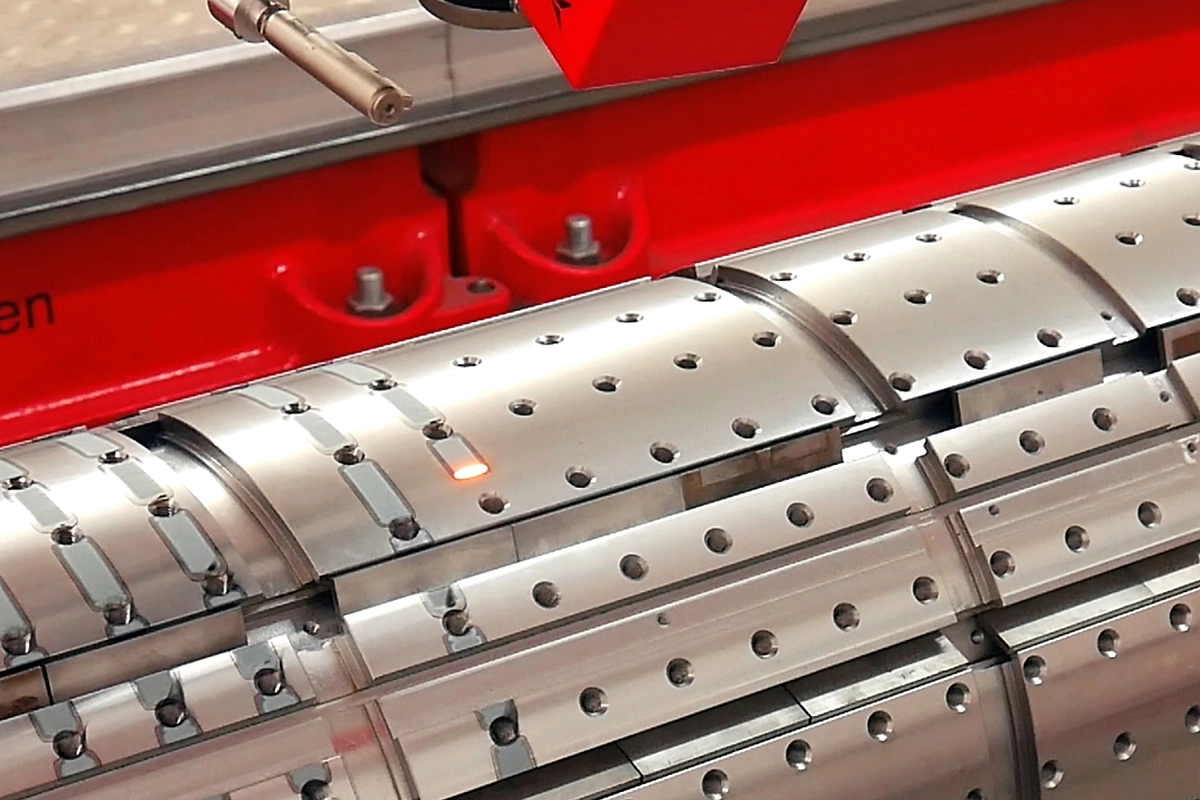

Mobile laser hardening of 14 m long and 25 t heavy pressure sleeves.

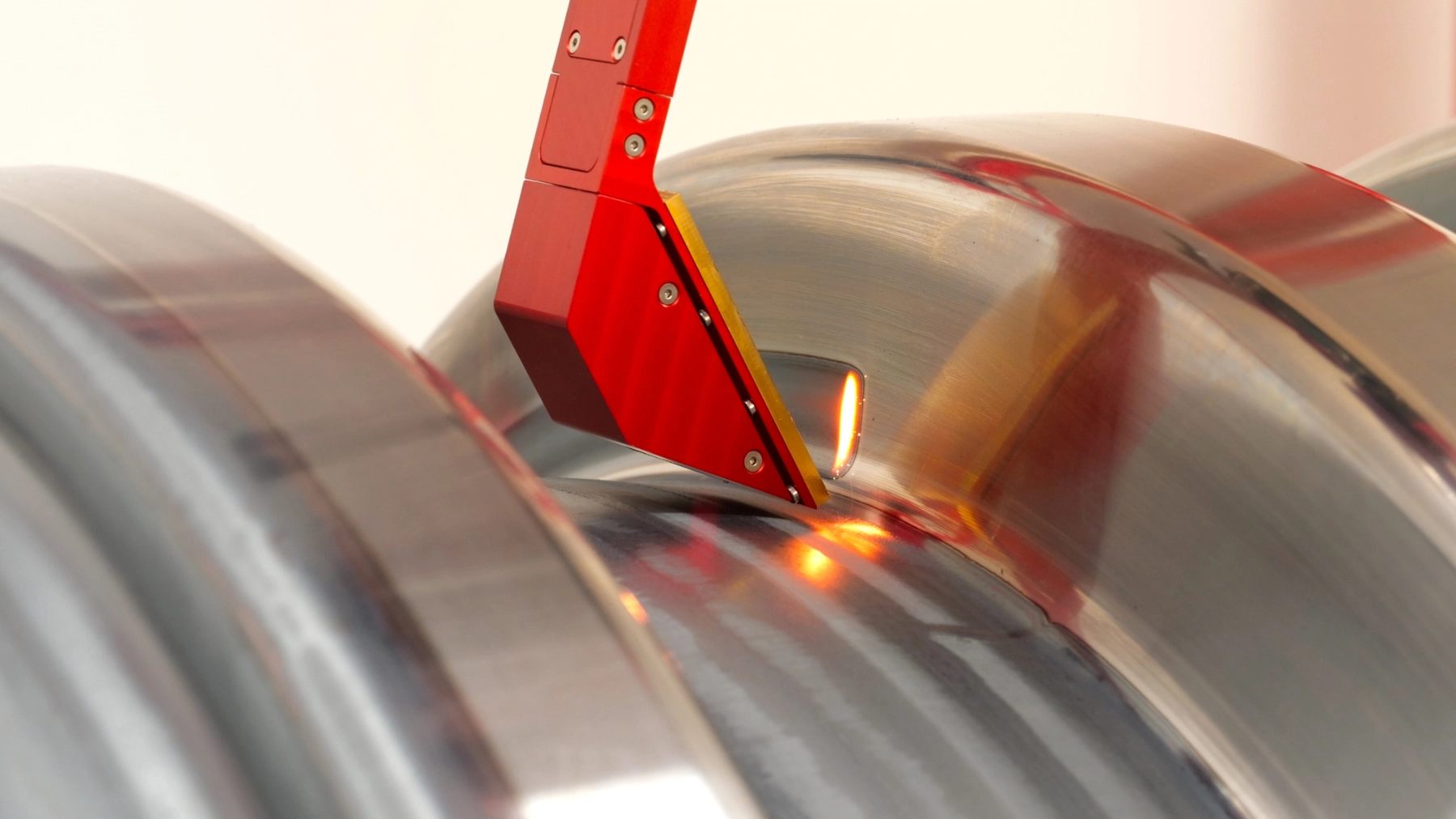

Laser hardening of a bevel gear with variable spot size during the hardening process.

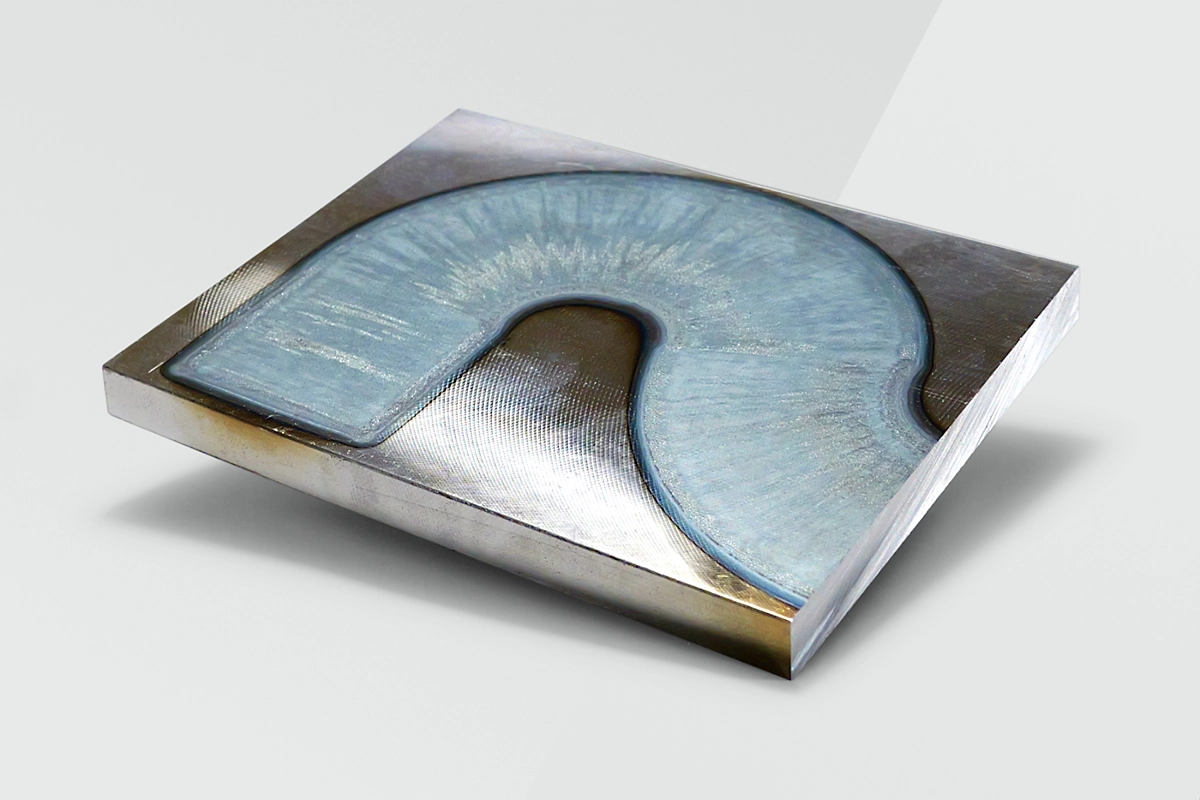

Laser hardening of a 3D free-forming surface with dynamic laser beam guidance for demanding component geometries in a forming die.

Laser hardening of a bending tool for a significantly longer service life.

With the mirror system, we can reach difficult areas such as deep-drawn edges or internal surfaces of rollers or pipes during surface hardening.

Laser hardening of larger tool surfaces of a pressing tool for the production of car body components for the automotive industry.

Laser hardening independent of the geometry: radii, V-grooves, multiple steps or edges by means of dynamic, scan-like oscillating movement of an oscillating mirror.

Laser hardening along the closing edge of a forming tool.

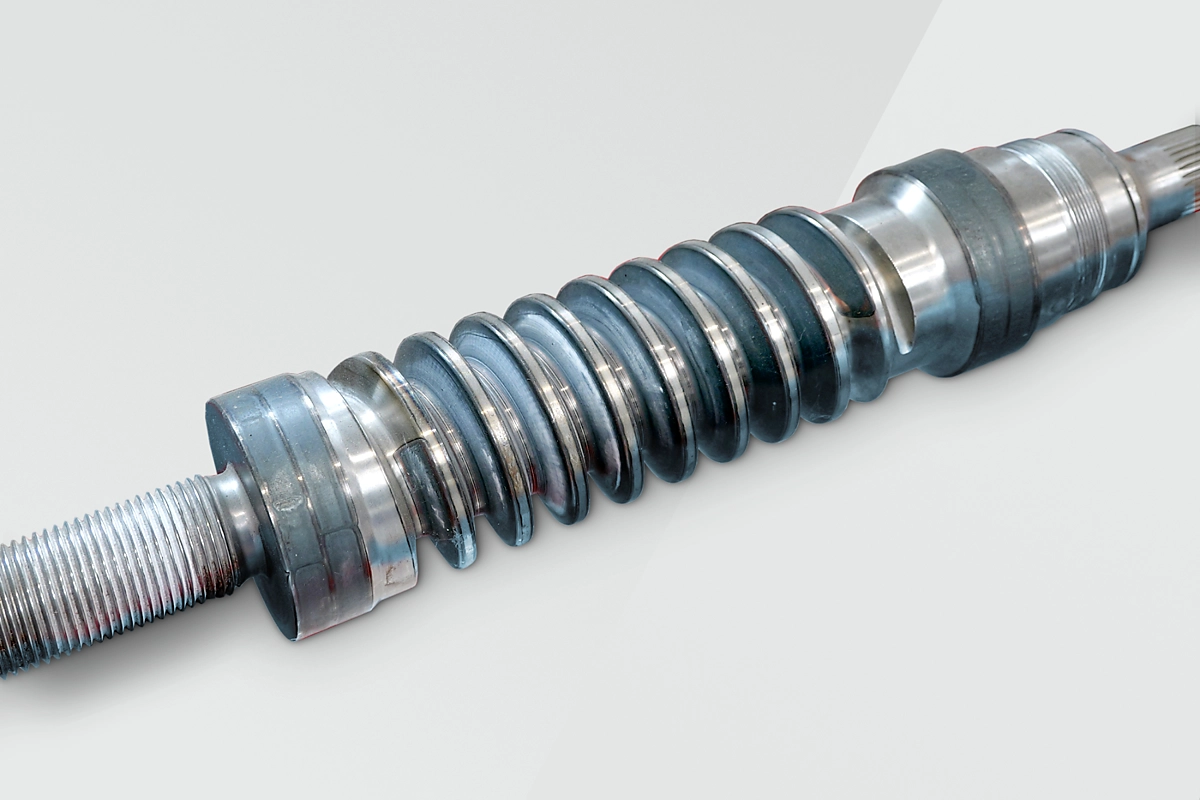

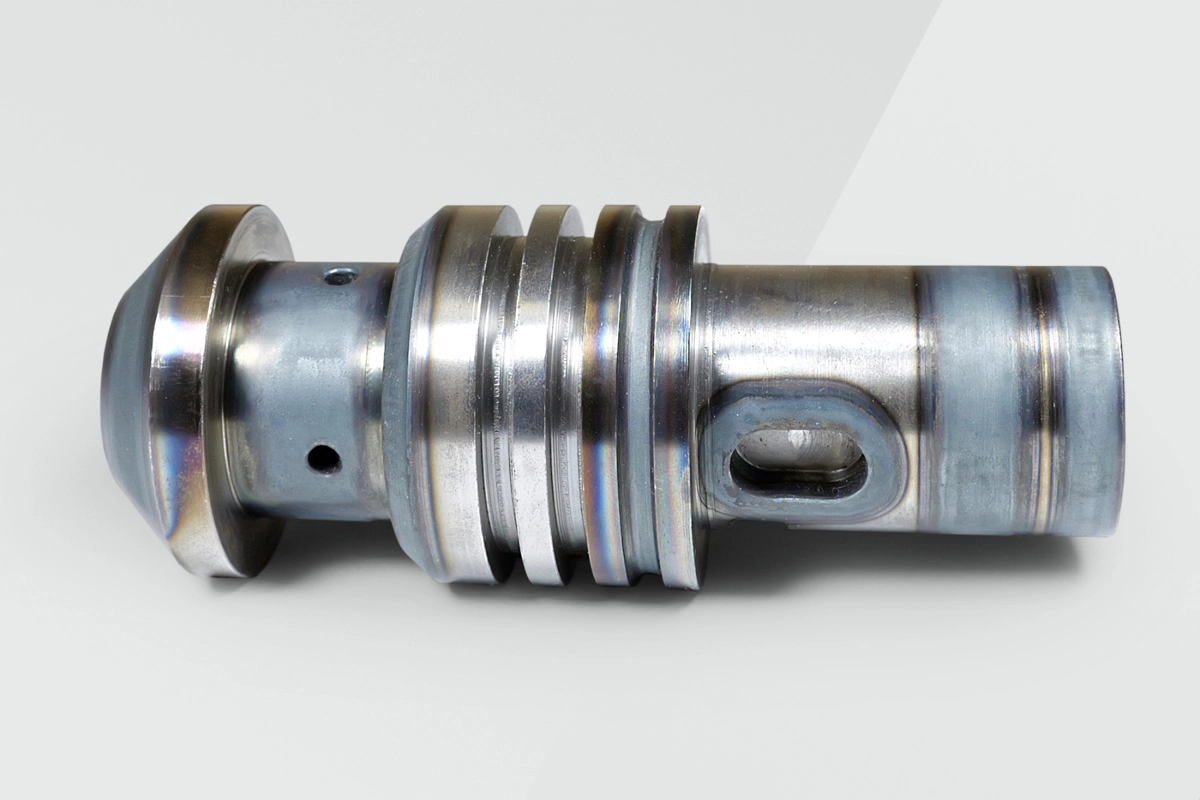

Laser hardening of a cylindrical machine component with different spot sizes.

Laser hardening of a forging roll for longer service life and therefore greater cost-effectiveness.

Comparison of hardening processes

Laser hardening offers numerous advantages, particularly with regard to low distortion and reduced post-processing costs. Conventional hardening processes can result in considerable distortion, which requires complex and expensive post-processing steps such as grinding to size. Laser hardening, on the other hand, enables precise and targeted heat treatment that reduces distortion to a minimum.

Alternative hardening processes compared to laser hardening:

A convincing example of the advantages of laser hardening are gear racks that we process for a customer: By switching from induction hardening to laser hardening, post-processing costs were reduced by an impressive 30 %. This economic advantage makes laser hardening an attractive choice for companies looking to increase efficiency and reduce costs.

Technology for all component shapes

Depending on the geometry of the component, different processing optics ensure the optimum surface hardness.

ALOhard

Laser hardening with fixed laser track width

ALOhardzoom

Laser hardening with variable laser track width

ALOhardscan

Laser hardening with dynamic laser beam guidance

ALOhardmirror

Laser hardening with deflection mirror

Focus on technology and components

Experience the precision and efficiency of laser hardening in action! In our videos, we show you how state-of-the-art technology and years of expertise come together to make your components even more durable and efficient.

Mobile laser hardening of 25-ton pressure sleeves

Laser hardening directly at the customer’s site! 14-metre-long and 25-ton pressure sleeves of an open-die forging press successfully hardened using mobile laser technology!

Laser hardening of a drive wheel with Ø 510 mm

Laser hardening of a drive wheel with a diameter of 510 mm, 83 teeth and made of 42CrMo4 material. Here, the tooth geometry is specifically hardened to 56 HRC.

Laser hardening of a forming tool

Laser hardening along the closing edge of a mold is used to harden high-strength plastic mold steels in a targeted manner and reduce wear.

Laser hardening of a roller with a mirror system

With the mirror system, we can reach hard-to-reach areas of the component during laser hardening, such as deep-drawn edges or internal surfaces.

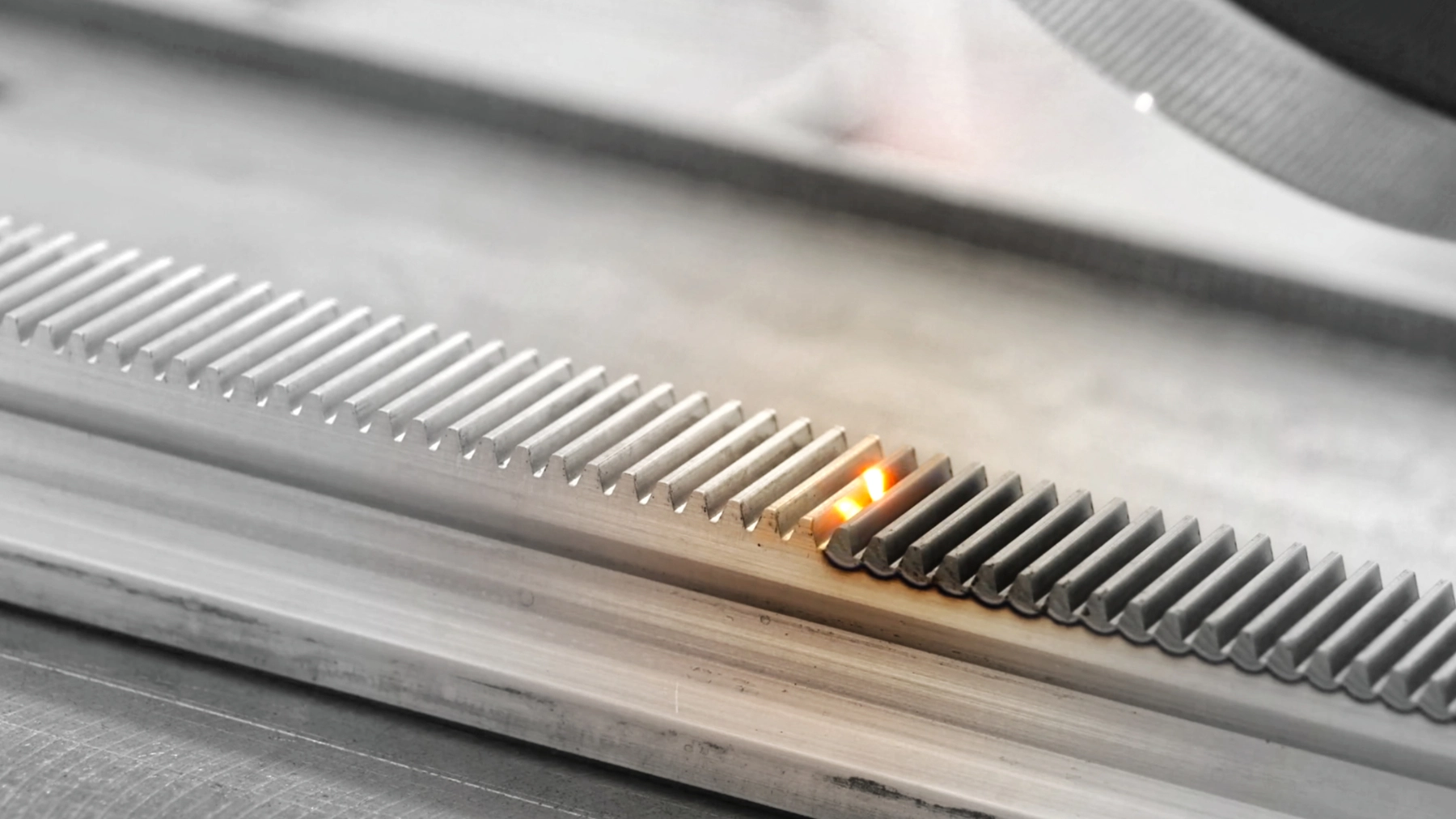

Laser hardening of gear racks with zoom optics

The precise laser hardening of the tooth flanks ensures high gear quality and a long service life. The targeted and localized application of heat results in very little distortion of the component.

Laser hardening of a 1.8 t cylinder component

Laser hardening with precision, even for large components – such as this cylinder component with a length of approx. 3.6 meters, a diameter of approx. 0.5 meters and a weight of 1.8 tons.

Process and quality assurance

With our in-house metallography, we support the development of your process and thus ensure the best possible quality and the most efficient process. Take advantage of sample production in the run-up to production to ensure optimum results on the components to be machined.

We offer the following testing methods in our metallography department:

Hardness depth profile measurement on material 51CrV4:

What others think about us

“We have actively opted for laser hardening for selected projects because we are very satisfied with the performance and would like to pass on the benefits of laser hardening to our customers!”

Laura Erbert, Project management Getriebebau Nossen

Your cost advantage:

We offer laser hardening as well as laser powder cladding directly on site at the component.

This eliminates transportation and set-up times for the component as well as the associated costs and risks.

Answers to your questions

Here you will find answers to the most frequently asked questions about laser hardening. Our aim is to help you quickly and easily. If you cannot find the right answer here, please do not hesitate to contact us directly.

01.

02.

03.

04.

05.

06.

07.

08.

09.

10.

11.